What can we design for you today? Talk to a building specialist to learn more. 1-888-449-7756

Compare Pole Barns

Olympia Steel Buildings vs. Pole Barns

Olympia Steel Buildings offers a superior metal building that will last a lifetime compared to a competitor’s pole barn.

Roof Panels

Olympia Steel Buildings

Olympia’s roof panels are made of 26-gauge AZ55 Galvalume® steel with a yield of 80,000 PSI and a huge corrugation depth of 1¼”. The strength of the steel together with the high PSI yield and deep corrugation create tremendous protection against strong winds and heavy snow loads.

The Galvalume coating contains 55% aluminum, 44% zinc and 1% silicon requiring no maintenance or painting since the roof retains its original luster. The greater aluminum content creates a higher resistance to rust. Olympia offers a 40-year limited perforation warranty on roof panel.

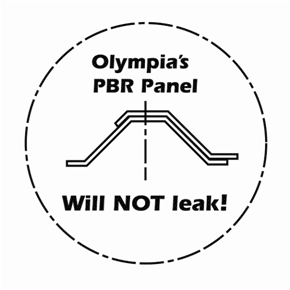

Olympia’s purlin bearing roof system (PBR) provides a full overlap preventing water from leaking into the building during storms when strong winds force rain against the overlap. Where the sheeting overlaps, the panel runs all the way to the bottom of the corrugation and along the bottom like a reverse “L.” The top PBR panel resembles a “Z” and overlaps the bottom panel providing additional strength as well as protection against leakage.

Olympia’s purlin bearing roof system (PBR) provides a full overlap preventing water from leaking into the building during storms when strong winds force rain against the overlap. Where the sheeting overlaps, the panel runs all the way to the bottom of the corrugation and along the bottom like a reverse “L.” The top PBR panel resembles a “Z” and overlaps the bottom panel providing additional strength as well as protection against leakage.

Pole Barns

The roof and sidewall panels of some competitors’ buildings are 29-gauge steel. With lighter steel, these buildings are less durable and not as strong as a 26-gauge Olympia building. In addition some pole barn companies utilize a 5/8″ corrugation on their roof panels that equates to half the strength of the 1¼” corrugation of an Olympia panel.

Some competitors offer only a 20-year perforation warranty, 20 years less than Olympia’s 40-year limited warranty. Many of these companies use a zinc-galvanized coating, which contains no aluminum or an AZ50 coating. The AZ50 coating contains less aluminum and, therefore, has less rust resistance.

An “R” roof panel system is used by some pole barn companies. The overlap only extends 1/3 of the way into the corrugation of the connecting sheet and is not sufficient to give strength to the joint. Water can build up in the corrugation where the panels overlap. Strong winds can push the water build up through the overlaps and into the building causing tremendous leaks.

Fasteners

Olympia Steel Buildings

Olympia’s roof and sidewall fasteners utilize screws that are supplied with assembled neoprene washers. The washers eliminate the potential for rust by preventing damage to the sheeting, such as cracking paint due to over-tightening screws. These washers also prevent screws from widening holes that can cause leaks.

Stainless steel screws are 18 parts chrome and 8 parts nickel and have painted heads that match the color of the sheeting. They will not rust, tarnish, turn dark gray or black.

Pole Barns

Many companies do not provide washers to prevent over-tightening. Over-tightening causes holes to widen and paint to crack and chip creating a source for leaks and corrosion. Fasteners that are not compatible with the roof sheeting will void the warranty.

Some competitors may offer long-life alloy screws, which do prevent rust. However, these screws will oxidize and turn dark gray or black detracting from the building’s appearance.

Painted Panels

Olympia Steel Buildings

Olympia’s sidewall panels carry a 40-year limited paint warranty against chipping, cracking, peeling or blistering. The paint is a siliconized polyester coating. A substrate galvanized coating beneath the paint provides further protection against rust.

Pole Barns

Many companies do not provide washers to prevent over-tightening. Over-tightening causes holes to widen and paint to crack and chip creating a source for leaks and corrosion. Fasteners that are not compatible with the roof sheeting will void the warranty.

Some companies only offer a 10-year warranty and others a 20-year warranty on the painted panels.

Secondary Framing

Olympia Steel Buildings

Olympia’s girts and purlins have a zinc galvanized coating, which is applied at the mill to protect against rust and prevent unsightly rust streaks on the interior panels. This secondary framing will not rust, warp or bend and is not subject to termites. Since Olympia buildings are made of steel, they are not subject to fire hazards which can result in a 35-40% insurance savings.

Pole Barns

Pole barns have wooden girts and purlins, which will bow and warp. This causes sheeting screws to loosen and holes to widen creating leaks. Wood is subject to fire hazards and termite infestation resulting in higher insurance costs.

Rigid Framing

Olympia Steel Buildings

The web in the rafter beams and columns is a solid steel plate design and the flanges on the sides of the web are made of solid steel bar stock. The frames are manufactured in an “H” configuration using automated continuous welding equipment. A minimum ¼” flange thickness stops beams from bowing.

Due to the fact that rafters are not tied together with cord, birds are unable to roost eliminating the opportunity for them to defecate on machinery stored in the building. In addition, the prospect of avian influenza spreading through bird droppings to other livestock is minimized.

Pole Barns

As with girts and purlins in pole barns, trusses and rafters are made of wood and subject to fire hazards and termite infestation. Insurance rates are higher for these reasons.

The cord at the bottom of pole barn rafters allow birds to perch and defecate on machinery stored below causing deterioration of equipment. Avian influenza is spread through bird droppings and introduces the possibility of the disease spreading to livestock housed in the building.

Pole Barn rafter configuration results in the loss of 20-25% of functional space in the building and a decrease in energy efficiency.

©2009-2024 King David Interactive Corp. All Rights Reserved. | CALL TO SAVE NOW! 1-888-449-7756