What can we design for you today? Talk to a building specialist to learn more. 1-888-449-7756

How Steel-Framed Vehicles Have Changed

While vehicles of all types have used steel in their construction from the very beginning, the way steel is currently being used to build vehicles has changed. This is because the process used to create steel has been refined over the years, and the steel used today is stronger and more durable than that used by Henry Ford in his first vehicle.

By changing the actual micro structure of the steel itself, the metal used today is much, much stronger. This new manufacturing technique was implemented to increase the safety of cars. The vehicles that use this steel are much more likely to survive a high-speed impact and protect the driver and passengers, even if less steel is used in the vehicle’s frame.

Another benefit from these new refinements and manufacturing processes is that today’s steel is actually lighter. It may seem to be counter-intuitive, but this lighter steel is stronger than some of its heavier counterparts, and because it’s lighter, the vehicle gets better gas mileage.

While vehicles of all types have used steel in their construction from the very beginning, the way steel is currently being used to build vehicles has changed. This is because the process used to create steel has been refined over the years, and the steel used today is stronger and more durable than that used by Henry Ford in his first vehicle.

By changing the actual micro structure of the steel itself, the metal used today is much, much stronger. This new manufacturing technique was implemented to increase the safety of cars. The vehicles that use this steel are much more likely to survive a high-speed impact and protect the driver and passengers, even if less steel is used in the vehicle’s frame.

Another benefit from these new refinements and manufacturing processes is that today’s steel is actually lighter. It may seem to be counter-intuitive, but this lighter steel is stronger than some of its heavier counterparts, and because it’s lighter, the vehicle gets better gas mileage.

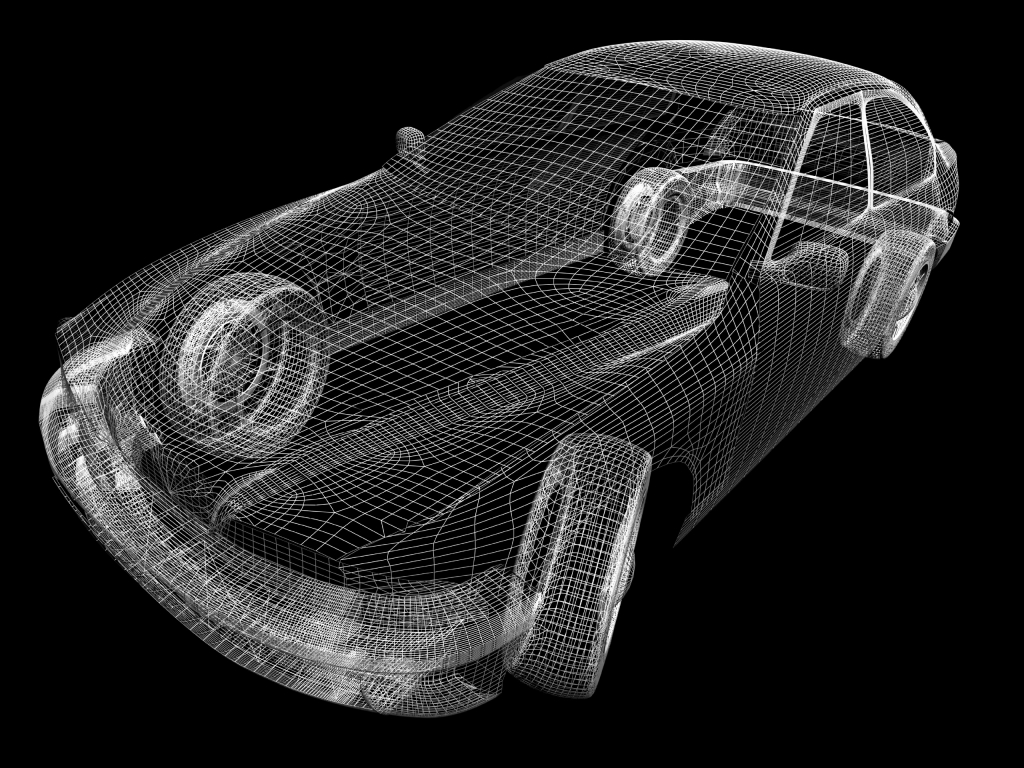

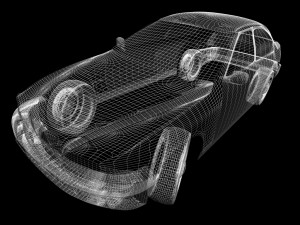

Originally, most car frames were made from one grade of steel. Today, though, different types are used in different parts of the frame. This patchwork job might not look as elegant when the car is stripped down to its bare bones, but it makes much more sense. It allows manufacturers to better tailor the vehicle to specific needs. More durable steel can be put in areas such as the front part of the car and in the doors to protect the driers, for example, while lighter steels can be used in the undercarriage.

These ultra-high strength steels have some very unusual properties, too. Some, such as the steel used in the front and the back of vehicles, is actually designed to crumple more easily. However, as it does, it gets much stronger. When tested against steel that doesn’t bend as easily, the new metal actually provides more safety due to its increased strength.

All of these newer steels can be used to make thinner frame pieces that provide as much or more durability for less to improve speed and gas consumption. However, there does reach a point where steel simply can’t be made any thinner without becoming too flexible. That has already happened in some areas, such as the exterior panels of a vehicle. These panels may be so thin that they’re actually less than one millimeter thick.

Despite these changes, some of the steel in automobiles has been replaced with materials like aluminum. However, most vehicles today are still at least 60 percent steel.

Originally, most car frames were made from one grade of steel. Today, though, different types are used in different parts of the frame. This patchwork job might not look as elegant when the car is stripped down to its bare bones, but it makes much more sense. It allows manufacturers to better tailor the vehicle to specific needs. More durable steel can be put in areas such as the front part of the car and in the doors to protect the driers, for example, while lighter steels can be used in the undercarriage.

These ultra-high strength steels have some very unusual properties, too. Some, such as the steel used in the front and the back of vehicles, is actually designed to crumple more easily. However, as it does, it gets much stronger. When tested against steel that doesn’t bend as easily, the new metal actually provides more safety due to its increased strength.

All of these newer steels can be used to make thinner frame pieces that provide as much or more durability for less to improve speed and gas consumption. However, there does reach a point where steel simply can’t be made any thinner without becoming too flexible. That has already happened in some areas, such as the exterior panels of a vehicle. These panels may be so thin that they’re actually less than one millimeter thick.

Despite these changes, some of the steel in automobiles has been replaced with materials like aluminum. However, most vehicles today are still at least 60 percent steel.

©2009-2024 King David Interactive Corp. All Rights Reserved. | CALL TO SAVE NOW! 1-888-449-7756